| INTERNATIONAL APPROVED |

| For decades, KL DOWN’s down products are sold to Europe, America and Asia. There are lots of demanded requirements from different customers. And those are the challenges to our customization ability. The quality of KL DOWN are trusted by our customers around the world and the quality standards of KL DOWN have been proved to be beyond the market requirements. |

| |

|

|

|

|

|

|

| The International Down and Feather Bureau (IDFB) was founded in 1953 which is the international trade association of down/feather. Only if the company is referred by the member can it join IDFB. KL DOWN is a member of IDFB and its committee of technology because of its reliabilities and capabilities in the down industry. Moreover, technicians of quality control in KL DOWN are trained and certified by the International Down and Feather Testing Laboratory (IDFL) which is the global leader in down, feather and textile product testing. Our quality control is as good as IDFL. We also exchange with local institute of down and feather testing to make sure that our products are qualified for local markets. |

|

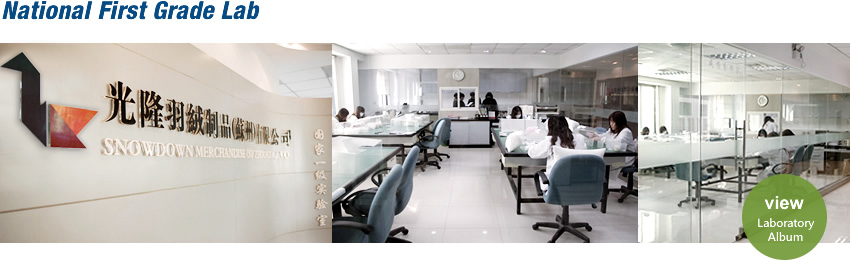

| Advanced Testing Instructions For Down Products |

| More and more healthy and environmental regulations have emerged. So the customers are not satisfied with existing quality control. KL DOWN has noticed this trend and has worked for water resources, carbon footprints and safety to humans in order to be certified with OEKO-TEX® 100 class I to IV which is applied to products for infants and children. Due to the restrictions of bluesign® that restricts lots chemicals from using on the textiles, it is necessary to set up the physical and chemical tests for down and feather. There are four strict tests run by KL DOWN Lab, including “Analysis of ultrastructure of down fibers”, “Quick analysis of chemicals”, “Analysis of trace chemicals” and “Microbiological testing”. |

| Analysis of Ultrastructure of Down Fibers |

| Field emission – Scanning Electronic Microscopy/ Energy Dispersive Spectrometry (FE-SEM/EDS) |

| The special three-dimensional structure of down makes the air which has low conductivity for heat to be an insulator. Integrity of down fibers affect the stability and sustainability of the structure. Damages of down material are hard to be seen with the naked eye. However, FE-SEM provides detailed observations of down to enhance the effectiveness of down processing. In addition, EDS detects residual elements to make sure that less contamination during down processing. |

|

Integrity of fiber structure of down

Damage of down structure

Sustainability of down products |

|

|

Trace elements on the surface of down fiber

Monitoring heavy metal and toxic elements |

|

|

|

| Quick Analysis of Chemicals |

| UV/VIS Spectrophotometer ; FT-IR Spectrometry |

| For functional down products, post-treatment by special functional chemicals is necessary. Chemical reaction between functional chemicals and the surface of down will improve the durability of down products. Fourier-transform infrared spectroscopy works to detect the combine between chemicals and the surface of down. It provides useful information to develop and improve functional down products. UV/VIS spectrophotometer is used to detect the restricted chemical substances in the functional down product. |

|

Analysis of post-treatment and finishing |

|

Stability of functional treatment |

|

|

Qualitative and quantitative analysis of the restricted chemicals |

|

Quick detection of restricted chemicals |

|

|

|

| Analysis of Trace Chemicals |

| Equilibrium headspace – gas chromatography/mass spectrometry (HS-GC/MS) NIST Chemical database |

| Because the requirement of bluesign® standards and REACH are expanding, more and more toxic chemicals are listed and banned. We set up a monitoring system from import to export. GC/MS is suitable to detect detected trace chemicals and listed on local market standard regularly. GC/MS chemical database is synchronized to NIST (National Institute of Standard Technology, USA), so we can find the information of the known components directly from GC/MS. GC/MS provides more reliable information apart from the substance data sheet from suppliers. Furthermore, equilibrium is adopted to find several organic chemicals which vapor easily, stink and do human harm. |

|

Analysis of banned or restricted chemical substances

Detection of residual chemicals by market standards |

|

|

Analysis of vapor and odor

Detection of steam organic chemicals and green-house gas |

|

|

|

| Microbiological Testing |

| Membrane-Filtration/Selective Culturing |

| The warehouse and farm are easy to get contaminated when the raw down materials are collected. Large amount of pathogenic, such as Salmonella sp. and Escherichia coli, will attach to the down materials. The amount of residual pathogenic and non-pathogenic bacteria is an index of the washing processing. However, the protocols of market standard methods for down are outdated. Full microbiological testing system in KL DOWN Lab is adopted in pharmaceutical. Membrane-filtration method and selective culturing make it easy and precise to detect bacteria from down products. |

|

Amount of total bacteria

Monitoring the hygiene of down products |

|

|

Analysis of specific pathogenic bacteria

Detection of pathogenic bacteria from down products |

|

|

|

| In view of environmental protection, KL DOWN set up advanced physical and chemical testing system for down materials and products. All of the instruments and testing methods are equal to or higher than third-party. They can not only guarantee the clients’ safety but be eco-friendly. |

|

|

|

|